Nature, not machinery, works hard - so you benefit

"There are over a million worms in the top humus layer of the BioPod – all waiting for their morning cafe latte."

– Dean Cameron, Inventor and Founder of Biolytix.

Why use high-energy mechanical aerators up to 24 hours a day to inject oxygen into wastewater - when the energetic worms and other organisms in the Bio-Pod will continually treat the wastewater using the oxygen from the ambient air in the Bio-Pod?

Letting nature do the aeration on a typical on-site wastewater system eliminates more than 1000kWhours per year....equivalent to watching TV 10 hours each day and reduces your carbon footprint by more than 1 tonne of CO2 per year.

An Environment Bay of Plenty Council trial of seven major sewage systems showed Biolytix used by far the least electricity of all of them.

The Council report on the Bio-Pod stated:

“One outstanding aspect of this system was its low electricity usage. It used as little as 5% or less of the electricity of some other systems measured.”

- On-site Wastewater Treatment System Environmental Discharge Performance Appraisal May 2007. Environmental Bay of Plenty Regional Council.

The BioPod harnesses the energy in the waste (including the sewage, toilet paper and food waste) to nourish the organisms that break down the waste. Nothing is wasted!

"There are over a million worms in the top humus layer of the BioPod – all waiting for their morning cafe latte."

– Dean Cameron, Inventor and Founder of Biolytix.

Why use high-energy mechanical aerators up to 24 hours a day to inject oxygen into wastewater - when the energetic worms and other organisms in the Bio-Pod will continually treat the wastewater using the oxygen from the ambient air in the Bio-Pod?

Letting nature do the aeration on a typical on-site wastewater system eliminates more than 1000kWhours per year....equivalent to watching TV 10 hours each day and reduces your carbon footprint by more than 1 tonne of CO2 per year.

An Environment Bay of Plenty Council trial of seven major sewage systems showed Biolytix used by far the least electricity of all of them.

The Council report on the Bio-Pod stated:

“One outstanding aspect of this system was its low electricity usage. It used as little as 5% or less of the electricity of some other systems measured.”

- On-site Wastewater Treatment System Environmental Discharge Performance Appraisal May 2007. Environmental Bay of Plenty Regional Council.

The BioPod harnesses the energy in the waste (including the sewage, toilet paper and food waste) to nourish the organisms that break down the waste. Nothing is wasted!

The components of a BioPod Sewage Treatment System:

A single, compact tank

This is normally a 3000 litre polymer tank (1.88m diameter by 2.06m high). The BioPod is the most compact biological treatment system in the world that we know of – making it easier to transport, less disruptive to install and unobtrusive. To put this in perspective a typical Sand Filter System (with a septic first stage, sand filter bed and pump chamber) would take up an area approximately 9 times larger than the Bio-Pod.

This is normally a 3000 litre polymer tank (1.88m diameter by 2.06m high). The BioPod is the most compact biological treatment system in the world that we know of – making it easier to transport, less disruptive to install and unobtrusive. To put this in perspective a typical Sand Filter System (with a septic first stage, sand filter bed and pump chamber) would take up an area approximately 9 times larger than the Bio-Pod.

|

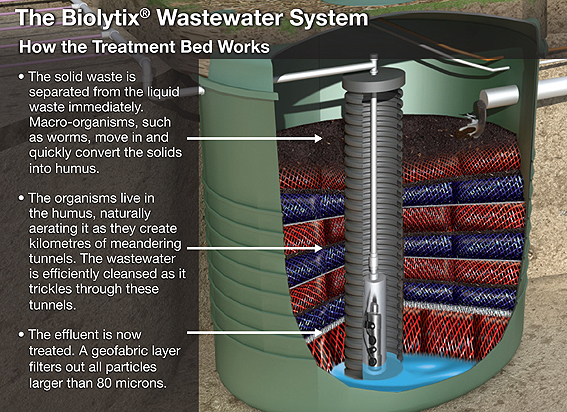

Inside the tank

The tank includes a layered filter bed, engineered separate the solids from the liquid wastewater and to house the organisms that quickly convert separated solids to a stable humic layer. The organisms, including worms, ensure the filter bed is naturally aerated, so that there is none of the smell associated with septic tanks and mechanically aerated wastewater systems. The ecosystem maintains the humus indefinitely, so the system only needs one annual service (most competing systems require 3-4 services each year). Near the bottom of the tank is a geofabric layer, which removes fine solids down to 80 micron size and is continually biologically cleansed. Below this is the purified water ready to be pumped to the garden. |

A tiny “fish tank” air pump for ventilation

A clear advantage of the BioPod is that is not reliant on complex or expensive machinery to run. Its tiny, but robust, air pump ensures aeration of the treated water collected at the bottom of the filter. It only consumes 0.12 kWh per day. This energy use is very low compared to conventional aerated wastewater systems, which typically consume between 2.5 to 6 kWh per day for treatment. This is 20 times more energy than a BioPod! Their large pumps can also be noisy – droning for up to 24 hours a day.

A clear advantage of the BioPod is that is not reliant on complex or expensive machinery to run. Its tiny, but robust, air pump ensures aeration of the treated water collected at the bottom of the filter. It only consumes 0.12 kWh per day. This energy use is very low compared to conventional aerated wastewater systems, which typically consume between 2.5 to 6 kWh per day for treatment. This is 20 times more energy than a BioPod! Their large pumps can also be noisy – droning for up to 24 hours a day.

An industrial strength irrigation pump

This pumps the treated water to the irrigation field. It is a single-phase pump. To dampen any pumping noise, it is engineered into the middle of the BioPod. The pump is also protected here from vandalism or theft.

This pumps the treated water to the irrigation field. It is a single-phase pump. To dampen any pumping noise, it is engineered into the middle of the BioPod. The pump is also protected here from vandalism or theft.

Audio-Visual Alarm

The BioPod is extremely reliable but an audio visual alarm installed in our near your house will let you know of any irregularities within your system.

The BioPod is extremely reliable but an audio visual alarm installed in our near your house will let you know of any irregularities within your system.

|

The Biolytix Patent

Biolytix own the patent for the Biolytic Filtration Process, which consists of the simultaneous treatment of wastewater and solid organic waste material on a bed of solids in various stages of decomposition, ranging from raw unprocessed organic material added to the surface of the bed, through to fully decomposed humus which is a very active filtration matrix and which forms the bulk of the bed. The bed is kept from blocking through the action of a farm of living organisms selected from worms, insects, crustaceans, mites and the like which create pores throughout the filtration matrix. This process cleverly turns the problem (the solid waste) into the solution (the humus that cleanses the wastewater). |

Biolytix copies nature

We understood that nature had the answers. For about a century, engineers have used water-based processes to treat wastewater. By studying ecology, nature's consummate engineer, Biolytix discovered that nature has a different solution: in nature, the most effective treatment doesn’t happen in water, but in moist soil ecosystems on rainforest floors and on river banks. This is where organisms convert waste into cleansing humus. The humus then helps cleanse the wastewater. Using worms and other organisms to break down organic waste is not an innovation - they have been doing so for millions of years. Our innovation is using nature's highly effective biological processes to solve today's challenge posed by wastewater. |

|

Uses the energy in the waste

Nothing wasted. The BioPod harnesses the energy stored in putrescible wastes, including toilet waste, household food waste and paper products, to nourish billions of microbes and a stable mix of invertebrate soil decomposer organisms. Grazers, grinders, predators and prey, all mix, aerate and break up the waste and convert it to fine humus. |

The Humus Filter

The key to efficient treatment. Worms and many other organisms quickly convert the solid waste into humus, one of the most powerful components of the BioPod. The humus is like a rich organic top soil. Worms and beetles continually burrow through it and keep it open, free draining and aerobic. They maintain it in a sponge-like structure, with many kilometers of oxygenated tunnels. It is this large surface area that aerates and cleanses the wastewater as it trickles through. This humus filter ensures:

|

Land Dispersal via dripline irrigation

The dispersal of treated effluent to land is the ultimate in sustainable disposal options. If correctly designed and controlled water and residual nutrients in the treated effluent can be dosed to plant root zones and beneficially utilised.

Subsurface disposal through pressure compensating dripline offers the following advantages:

The BioPod is supplied with a standard dripline irrigation kit to allow for the controlled dispersal of treated wastewater into or onto the topsoil in your backyard. The dripline is a flexible and easy to install polyethylene dripline with pressure compensating turbulent flow emitters which distributes effluent slowly and uniformly across the entire disposal area even in difficult soils and hilly terrain.

The Bio-Pod utilises Wasteflow dripline which is designed specifically for dispersal of treated effluent and which has two key advantages that no other dripline offers:

The major advantages of a sub-surface irrigation system:

1. Grows more with less

Have a lush garden all year. The sub-surface irrigation helps you save water. It targets the root zone, where it is needed most. Far less valuable water is lost through evaporation, spray drift and run-off.

2. Safeguards your family and pets

Sub-surface irrigation is your safest option. Even though the treated water from the BioPod exceeds a secondary standard, it is safest to keep it in the soil. The soil is an effective barrier to human contact with effluent. It eliminates the hygiene risks associated with pathogens in spray and puddles from above-ground irrigation.

As the risk from above-ground irrigation can be high, disinfection is required. If the disinfection system fails, or if the service intervals are not observed, the environmental and hygiene risks can be high.

3. Less intrusive and reduced on-going costs

The irrigation is out of sight, out of mind. No need to mow around sprinklers and pipes, as these are not exposed to damage from the mower.

4. More versatile

It is also better suited for steep slopes. In contrast, spray irrigation on steep slopes can cause soil erosion and run off, and is more likely to result in uneven distribution.

The dispersal of treated effluent to land is the ultimate in sustainable disposal options. If correctly designed and controlled water and residual nutrients in the treated effluent can be dosed to plant root zones and beneficially utilised.

Subsurface disposal through pressure compensating dripline offers the following advantages:

- The wetted volume of soil around the emitter is about 40% larger compared to surface installations

- It reduces the potential for human or domestic animal contact which is important as secondary treated effluent can still have high pathogen concentrations

- The potential for odours evident in the disposal area is reduced

- The potential for UV degradation or mechanical damage is reduced

The BioPod is supplied with a standard dripline irrigation kit to allow for the controlled dispersal of treated wastewater into or onto the topsoil in your backyard. The dripline is a flexible and easy to install polyethylene dripline with pressure compensating turbulent flow emitters which distributes effluent slowly and uniformly across the entire disposal area even in difficult soils and hilly terrain.

The Bio-Pod utilises Wasteflow dripline which is designed specifically for dispersal of treated effluent and which has two key advantages that no other dripline offers:

- Emitters are protected by Rootguard® technology which uses Treflan® herbicide to prevent roots growing into the emitter. The herbicide is impregnated into each drip emitter during the moulding process to direct root growth away from the drip emitter which stops root intrusion.

- Wasteflow is protected against slime growth on the inside walls by the use of Geoshield®. Geoshield is the green inner lining of the Wasteflow tube which is extruded with an anti microbial agent that inhibits organic growth inside the dripline. This allows any debris accumulating within the dripline system to be more easily flushed out during maintenance.

The major advantages of a sub-surface irrigation system:

1. Grows more with less

Have a lush garden all year. The sub-surface irrigation helps you save water. It targets the root zone, where it is needed most. Far less valuable water is lost through evaporation, spray drift and run-off.

2. Safeguards your family and pets

Sub-surface irrigation is your safest option. Even though the treated water from the BioPod exceeds a secondary standard, it is safest to keep it in the soil. The soil is an effective barrier to human contact with effluent. It eliminates the hygiene risks associated with pathogens in spray and puddles from above-ground irrigation.

As the risk from above-ground irrigation can be high, disinfection is required. If the disinfection system fails, or if the service intervals are not observed, the environmental and hygiene risks can be high.

3. Less intrusive and reduced on-going costs

The irrigation is out of sight, out of mind. No need to mow around sprinklers and pipes, as these are not exposed to damage from the mower.

4. More versatile

It is also better suited for steep slopes. In contrast, spray irrigation on steep slopes can cause soil erosion and run off, and is more likely to result in uneven distribution.

Servicing and Maintenance Care

The Biolytix BioPod has been designed to provide long-term, effective treatment of household sewage and wastewater. Just like your vehicle requires a service to run smoothly, correct operation and maintenance of the BioPod will ensure it operates at peak performance.

Biolytix BioPod only requires one annual service

No matter what wastewater treatment system you buy, you must comply with local Council regulations. These regulations require servicing of all on-site wastewater systems in accordance with manufacturer’s specifications and that the work is to be undertaken by an accredited technician.

The BioPod is so reliable it only needs one service annually to ensure it is performing well as opposed to quarterly servicing requirements for most other systems (Note: Some Councils require a minimum of two services per year regardless of the type of wastewater system).

Choosing a system with low on-going costs

When choosing a wastewater treatment system, you should consider ongoing replacement costs. The BioPod is a living ecosystem, which treats the waste naturally. Just like nature, the ecosystem works hard and continually replenishes itself - so there are no large mechanical aerators that can be expensive to run, fix and replace.

Other systems can be vulnerable to wear and tear and break down and often need replacement of expensive parts, such as pumps, blowers and membranes and the ongoing energy costs can be up to 90% more than the BioPod.

Most other systems need to be serviced up to 4 times a year and these quarterly servicing requirements can cost up to $200 each visit.

Biolytix BioPod product warranty

When you buy a Biolytix BioPod from an accredited Biolytix installer, you automatically receive our standard BioPod Warranty.

Biolytix Limited (NZ Company No.3265414) (“Biolytix”) warrants the Biolytix® Biopod will be free from defects in material and workmanship for the following periods of time, commencing on the date of installation, in accordance with the conditions.

The Vessel: 15 years The Pedrollo Pump: 2 years The BioPod: 1 year

Biolytix Water ... naturally ... the safe and cost-effective choice.

The Biolytix BioPod has been designed to provide long-term, effective treatment of household sewage and wastewater. Just like your vehicle requires a service to run smoothly, correct operation and maintenance of the BioPod will ensure it operates at peak performance.

Biolytix BioPod only requires one annual service

No matter what wastewater treatment system you buy, you must comply with local Council regulations. These regulations require servicing of all on-site wastewater systems in accordance with manufacturer’s specifications and that the work is to be undertaken by an accredited technician.

The BioPod is so reliable it only needs one service annually to ensure it is performing well as opposed to quarterly servicing requirements for most other systems (Note: Some Councils require a minimum of two services per year regardless of the type of wastewater system).

Choosing a system with low on-going costs

When choosing a wastewater treatment system, you should consider ongoing replacement costs. The BioPod is a living ecosystem, which treats the waste naturally. Just like nature, the ecosystem works hard and continually replenishes itself - so there are no large mechanical aerators that can be expensive to run, fix and replace.

Other systems can be vulnerable to wear and tear and break down and often need replacement of expensive parts, such as pumps, blowers and membranes and the ongoing energy costs can be up to 90% more than the BioPod.

Most other systems need to be serviced up to 4 times a year and these quarterly servicing requirements can cost up to $200 each visit.

Biolytix BioPod product warranty

When you buy a Biolytix BioPod from an accredited Biolytix installer, you automatically receive our standard BioPod Warranty.

Biolytix Limited (NZ Company No.3265414) (“Biolytix”) warrants the Biolytix® Biopod will be free from defects in material and workmanship for the following periods of time, commencing on the date of installation, in accordance with the conditions.

The Vessel: 15 years The Pedrollo Pump: 2 years The BioPod: 1 year

Biolytix Water ... naturally ... the safe and cost-effective choice.

| |||||||

Biolytix - your experienced wastewater specialists.

Our Story

We had been aware of the award winning Biolytix wastewater treatment solution for some time and were impressed with it unique yet intrinsically simple approach to achieving a relatively high level of wastewater treatment. The technology addressed a number of the shortcomings of the traditional alternatives available in market in particular the minimal energy use and the reduced number of mechanical components. Since becoming aware of Biolytix they have won numerous international awards for the technology, have performed outstandingly well at independent trials and developed a strong satisfied customer base in New Zealand and a network of Biolytix trained and registered drainlayers to install and maintain installed systems.

In January 2011, the opportunity presented itself for us to invest in the Biolytix products in New Zealand and we quickly formed a team that could give the technology the local representation it deserves. In February 2011, our team successfully purchased the Biolytix intellectual property for New Zealand and began manufacturing the Biolytix BioPod in Auckland to supply the New Zealand domestic on-site wastewater market.

We are now manufacturing and delivering the exact same product using the same components and manufacturing techniques and standards to ensure each BioPod leaving the factory has the highest level of quality assurance. We work directly with approved installers in each local region to ensure that Biolytix BioPod goes in the ground exactly as per the installation instructions and does that job that it is intended to do. We also continually liaise with engineers and Councils to ensure they have the latest technical specifications at their fingertips and that all installations are consistent with the latest District and Regional Plan requirements, Standards and Building and Resource Consent conditions.

In July 2011, we secured the Global Rights to manufacture the Biolytix patent and are looking forward to once again being in a position to share this product with the Australian and Pacific Island markets and beyond.

Our Story

We had been aware of the award winning Biolytix wastewater treatment solution for some time and were impressed with it unique yet intrinsically simple approach to achieving a relatively high level of wastewater treatment. The technology addressed a number of the shortcomings of the traditional alternatives available in market in particular the minimal energy use and the reduced number of mechanical components. Since becoming aware of Biolytix they have won numerous international awards for the technology, have performed outstandingly well at independent trials and developed a strong satisfied customer base in New Zealand and a network of Biolytix trained and registered drainlayers to install and maintain installed systems.

In January 2011, the opportunity presented itself for us to invest in the Biolytix products in New Zealand and we quickly formed a team that could give the technology the local representation it deserves. In February 2011, our team successfully purchased the Biolytix intellectual property for New Zealand and began manufacturing the Biolytix BioPod in Auckland to supply the New Zealand domestic on-site wastewater market.

We are now manufacturing and delivering the exact same product using the same components and manufacturing techniques and standards to ensure each BioPod leaving the factory has the highest level of quality assurance. We work directly with approved installers in each local region to ensure that Biolytix BioPod goes in the ground exactly as per the installation instructions and does that job that it is intended to do. We also continually liaise with engineers and Councils to ensure they have the latest technical specifications at their fingertips and that all installations are consistent with the latest District and Regional Plan requirements, Standards and Building and Resource Consent conditions.

In July 2011, we secured the Global Rights to manufacture the Biolytix patent and are looking forward to once again being in a position to share this product with the Australian and Pacific Island markets and beyond.