Plus…it's small footprint makes it easy to install in even the smallest prep kitchens.

The Goslyn™ Separator is a patented, immiscible liquid separator which operates under hydrostatic pressure and has no moving parts. Proven in thousands of foodservice applications worldwide, the innovative Goslyn™ Separator employs an innovative multi-stage, patented technology to continuously and permanently remove Fats, Oils & Greases from waste effluent. Its up to 99.6% separation rate keeps drains free and clear, while eliminating the need for costly dousing systems and grease trap pumping…and it can capably handle flow rates over 250 gpm.

Goslyn™ Separators are specifically engineered to thoroughly collect and remove any solid debris that may bypass 'sink' strainers. It is typically these stray solids, mixing with fats, oils and grease that congeal to create costly drain blockages. Further reinforcing the Goslyn™ Separators’ solids collection capabilities, is a solids strainer basket that will capture solids greater than 2mm and effectively remove them from the waste stream.

Extremely user friendly, the newest Goslyn™ Separator has no moving parts to break and no messy grease traps to clean. Simply empty the oil cassette when full and easily clean out the solids strainer basket and oil valve at the end of the day. Less than 2 minutes a day is all it takes to keep your drains free and clear!

Goslyn™ Grease Recovery Technology constantly and automatically removes Fats, Oil and Grease (FOG) from the separation tank so there is no build-up of retained FOG as is the case for traditional grease traps. This important feature enables Goslyn™ Separators to indefinitely maintain a high rate of operating efficiency.

We invite you to take a closer look at the many features, benefits and reasons why the innovative Goslyn™ Separator is the most effective, and only FOG collection device you need to have in your kitchen or other food preparation facility.

Goslyn™ Separators are specifically engineered to thoroughly collect and remove any solid debris that may bypass 'sink' strainers. It is typically these stray solids, mixing with fats, oils and grease that congeal to create costly drain blockages. Further reinforcing the Goslyn™ Separators’ solids collection capabilities, is a solids strainer basket that will capture solids greater than 2mm and effectively remove them from the waste stream.

Extremely user friendly, the newest Goslyn™ Separator has no moving parts to break and no messy grease traps to clean. Simply empty the oil cassette when full and easily clean out the solids strainer basket and oil valve at the end of the day. Less than 2 minutes a day is all it takes to keep your drains free and clear!

Goslyn™ Grease Recovery Technology constantly and automatically removes Fats, Oil and Grease (FOG) from the separation tank so there is no build-up of retained FOG as is the case for traditional grease traps. This important feature enables Goslyn™ Separators to indefinitely maintain a high rate of operating efficiency.

We invite you to take a closer look at the many features, benefits and reasons why the innovative Goslyn™ Separator is the most effective, and only FOG collection device you need to have in your kitchen or other food preparation facility.

FOG is really better defined as AVFOGS…which is a much more all–inclusive acronym for Animal, Vegetable, Fats, Oil, Grease and Solids.

|

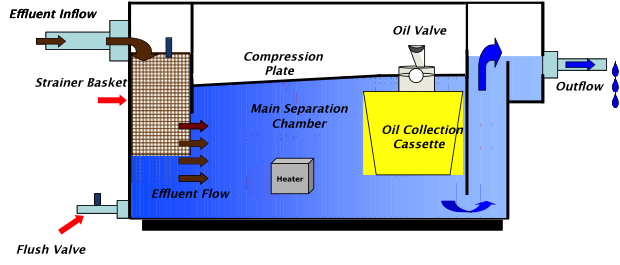

Stage 1: Waste Water (Effluent) Flow Control Effluent flow rates are controlled by the sized inlet flow restrictor to maintain operating efficiency and to prevent effluent surges. Stage 2: Food Removal

The effluent is channeled through a removable food strainer basket where unwanted food debris is automatically captured and retained. |

Stage 3: Oil Separation

The Goslyn™ innovative oil separation chamber operates under hydrostatic pressure at 40°C / 104°F for highly efficient oil separation.

Stage 4: Oil removal

Hydrostatic pressure forces 99.6% of FOG out through the oil discharge valve into the oil cassette while "clean" water is discharged into the sewer system.

Stage 5: Daily 2 Minute Maintenance

Food waste solids are removed from the removable strainer basket to a separate food collection container for disposal and/or composting FOG is drained from the removable oil cassette to a separate oil collection container fro rendering or conversion to bio-fuel The manually controlled flush valve is opened for 5 to 10 seconds, flushing the solids that are too fine to be trapped by the strainer basket.

The Goslyn™ innovative oil separation chamber operates under hydrostatic pressure at 40°C / 104°F for highly efficient oil separation.

Stage 4: Oil removal

Hydrostatic pressure forces 99.6% of FOG out through the oil discharge valve into the oil cassette while "clean" water is discharged into the sewer system.

Stage 5: Daily 2 Minute Maintenance

Food waste solids are removed from the removable strainer basket to a separate food collection container for disposal and/or composting FOG is drained from the removable oil cassette to a separate oil collection container fro rendering or conversion to bio-fuel The manually controlled flush valve is opened for 5 to 10 seconds, flushing the solids that are too fine to be trapped by the strainer basket.

|

Warranty

With no moving parts and rugged stainless steel construction, Goslyn™ Separators are built to last. And that fact is underscored by an industry leading 5 Year limited warranty that is a great added value benefit of every hard working - long running Goslyn™Separator.

Besides counting on Goslyn™ Separators to deliver the best in grease removal efficiency, you can also count on Goslyn™Separators to deliver the best in both low operating costs and an outstanding ROI.

What is the difference?

The terms “grease trap” and “interceptor” are often used interchangeably. The true difference, as defined by the Uniform Plumbing Code, is derived from the flow rate of each. Grease traps are usually small and found inside the kitchen. Interceptors are generally considerably larger and are located outside…typically a short distance from the building and underground. They can be identified by manhole covers, which provide access for regular pumping and cleaning.

Grease Traps…Generally unchanged for decades

In the late 1800’s Nathanial Whiting designed and received a patent for the passive gravity separator, the device known today as a grease trap. The common grease trap remains relatively unchanged today as a means of separating fats, oils and greases from wastewater. is a problem in almost every locale in the country

Grease traps are usually located near the sink. They slow the flow of grease on a baffle and “capture it” as floating material. Most of the heavier material…but not all…will sink to the bottom. This sediment must be properly removed at least once a week

A grease interceptor is an in-ground tank that is designed to limit the amount of FOG and solids from entering the sanitary sewer system. Interceptors hold FOG until it can be collected and removed by a recycling or rendering company. Interceptors are generally more effective than traditional grease traps and require monthly inspection and periodic cleaning.

The terms “grease trap” and “interceptor” are often used interchangeably. The true difference, as defined by the Uniform Plumbing Code, is derived from the flow rate of each. Grease traps are usually small and found inside the kitchen. Interceptors are generally considerably larger and are located outside…typically a short distance from the building and underground. They can be identified by manhole covers, which provide access for regular pumping and cleaning.

Grease Traps…Generally unchanged for decades

In the late 1800’s Nathanial Whiting designed and received a patent for the passive gravity separator, the device known today as a grease trap. The common grease trap remains relatively unchanged today as a means of separating fats, oils and greases from wastewater. is a problem in almost every locale in the country

Grease traps are usually located near the sink. They slow the flow of grease on a baffle and “capture it” as floating material. Most of the heavier material…but not all…will sink to the bottom. This sediment must be properly removed at least once a week

A grease interceptor is an in-ground tank that is designed to limit the amount of FOG and solids from entering the sanitary sewer system. Interceptors hold FOG until it can be collected and removed by a recycling or rendering company. Interceptors are generally more effective than traditional grease traps and require monthly inspection and periodic cleaning.

Ecological Impact

|

The environmental impact of AVFOGS above 30 mg / 1 in waste water streams can easily leads to the build-up of carcinogenic liquids and solids.

93% of all AVFOGS enter the drainage system as a result of warewashing, clean-up and general kitchen sanitation. The accumulation taxes drain lines, pumping stations, sewer lines and water treatment plants. Overflows from clogged pipelines and interceptors can easily overflow into sewer lines and even storm water drain lines that lead directly to water sources fouling streams, lakes, ponds, aquifers and groundwater. And animals, fish and plants that draw from polluted waters are at risk of toxic poisoning and other type of biologic contamination. |

Grease Management

|

The high efficiency separation and thorough entrapment of FOG output that Goslyn™ Separators can provide, enable users the ability to easily manage grease collection and disposal, while also eliminating blockage and overflow problems common to the use of traditional grease traps, interceptors and other GRD's.

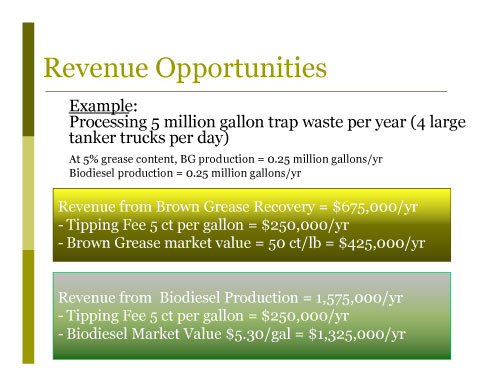

One important side benefit to the high grade separation of high grade grease and oils that can be produced Goslyn™ Separators, can enable users to create a profit center for the sale of high grade grease and oils to producers of bio fuels and other related products. Here is how one California city views potential revenue opportunities that could be generated from the collection of high grade FOG such as produced by Goslyn™Separators, and converting those organics to Biodiesel and allied derivatives. Depending upon which equipment Goslyn™ Separators are connected to, will dictate what type of grease is collected. For example…

"Yellow" Grease

The high grade yellow grease that Goslyn™ Separators produce is highly sought after by biodiesel converters and thus has marketable value. Other GRD's, are not designed to effectively collect yellow grease and instead produce brown grease and sludge, which are unpleasant to handle, represent the leading cause of costly pipeline blockages and must also be regularly professionally collected and removed by an independent service. |

Eliminates Overflows!Goslyn™ Separators are both ingeniously simple and tremendously effective. These advanced separators utilize multiple technologies to effectively and quickly separate FOGS from even the heaviest flow. Liquid discharge from Goslyn™ separators typically contains not more than 62 ppm FOG.

The bottom line? No more costly visits from plumbers to clear blocked piping and no more contamination of waste waster systems |

Markets

|

Anywhere that AVFOGS are being generated, is an application where Goslyn™ Separator technology should be installed.

Markets Served

|

|

The Clear Choice for Clean Waste Water Goslyn™ high efficiency liquid separators utilize multi-stage separation technology to significantly reduce the level of FOGS in waste water effluent. Typical FOG discharge using a traditional disposal is 18,500 ppm…compared to just 62 ppm from a Goslyn™ Separator. |