CONTENTSIn some cases Orenco's residential sized systems may be more appropriate for small businesses or commercial sites . . .

|

Applications:

• Municipal systems • Subdivisions, apartments • Golf course developments, resorts

• Manufactured home parks • Parks, RV parks, campgrounds

• Schools, churches, businesses • Rest areas, truck stops

• Municipal systems • Subdivisions, apartments • Golf course developments, resorts

• Manufactured home parks • Parks, RV parks, campgrounds

• Schools, churches, businesses • Rest areas, truck stops

|

The Product

Orenco’s patented* AdvanTex® Treatment Systems can make raw wastewater up to 98% cleaner, meeting stringent regulatory requirements. They can also reduce nitrogen significantly, depending on influent and configuration. Orenco’s commercial-sized (AX100) AdvanTex Systems offer all the benefits of Orenco’s residential line:

Decades of Research, Thousands of Installations Orenco’s AdvanTex recirculating filter unit is configured like a recirculating sand filter — a packed bed filter technology that Orenco engineers have helped to perfect since the 1970s. Like recirculating sand filters, AdvanTex is reliable and low-maintenance. It is superior to other packed bed filters, however, in its serviceability and longevity. It is also superior in its treatment media. AdvanTex uses a highly efficient, lightweight textile that has a large surface area, lots of void space, and a high degree of water-holding capacity. Consequently, AdvanTex Treatment Systems can provide treatment equivalent to that of sand filters at loading rates as high as 25-50 gpd/ft2 (1000-2000 L/d/m2). That means AdvanTex can treat high-volume commercial and multi-family flows in a very compact space. Our textile-based, multi-pass treatment technology has undergone third-party testing and evaluation to ANSI Standards. About 30,000 residential-sized AdvanTex filters have been installed since 2000. And about 3,000 commercial-sized AX100 units are now in operation, including the installations described below. |

Laterals and Lids

Isolation valves, flushing valves, and hinged lids with gas springs allow easy access and servicing by a single operator. The Program

It takes more than a good product to solve on-site wastewater problems. It takes a comprehensive program … one that ensures a successful project every time and provides support for the life of the system. That’s what Orenco Systems® has done. We’ve engineered a program, not just a product. Orenco’s commercial AdvanTex program includes …

|

Malibu Restaurant and Residential Development

Ten AX100s at the top of a Malibu bluff are treating high-strength waste from a large (200+ seat) beachfront restaurant, 100 feet (30 m) below. This high-visibility tourist destination requires reliable, odor-free operation. Effluent sampling indicates excellent treatment, including nitrogen reduction. At an adjacent residential community, another system has been installed, consisting of 20 AX100s capable of treating up to 60,000 gpd (227,000 L/d) peak flows.

Ten AX100s at the top of a Malibu bluff are treating high-strength waste from a large (200+ seat) beachfront restaurant, 100 feet (30 m) below. This high-visibility tourist destination requires reliable, odor-free operation. Effluent sampling indicates excellent treatment, including nitrogen reduction. At an adjacent residential community, another system has been installed, consisting of 20 AX100s capable of treating up to 60,000 gpd (227,000 L/d) peak flows.

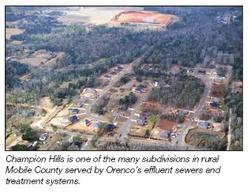

Mobile, Alabama

Utility-Managed Subdivisions

Since 2003, South Alabama Utilities (SAU) in Mobile County, Alabama, has become the subject of nationwide

classes, presentations, and tours because of its ambitious and innovative solution for serving nearly 4,000 new customers in 47 new subdivisions in western Mobile County (as well as a number of new schools and commercial properties). How?

By installing more than 60 miles (96.5 km) of interconnected Orenco Effluent Sewers that are followed by 141 AdvanTex AX100s located at 13 different treatment sites. All told, SAU has the capacity to treat nearly half a million gpd (1.9 million L/d) of effluent, at better than 10 mg/L BOD/TSS. Under SAU’s program, developers, builders, homeowners, and the utility all share the cost of extending wastewater infrastructure. Costs vary by development, but SAU currently charges homeowners about $35-40/month for service. Overall costs are about half the cost of conventional sewers.

Utility-Managed Subdivisions

Since 2003, South Alabama Utilities (SAU) in Mobile County, Alabama, has become the subject of nationwide

classes, presentations, and tours because of its ambitious and innovative solution for serving nearly 4,000 new customers in 47 new subdivisions in western Mobile County (as well as a number of new schools and commercial properties). How?

By installing more than 60 miles (96.5 km) of interconnected Orenco Effluent Sewers that are followed by 141 AdvanTex AX100s located at 13 different treatment sites. All told, SAU has the capacity to treat nearly half a million gpd (1.9 million L/d) of effluent, at better than 10 mg/L BOD/TSS. Under SAU’s program, developers, builders, homeowners, and the utility all share the cost of extending wastewater infrastructure. Costs vary by development, but SAU currently charges homeowners about $35-40/month for service. Overall costs are about half the cost of conventional sewers.

|

Oregon Riverside Community Since 2003, twelve AX100s have been providing advanced secondary wastewater treatment in Hebo, Oregon, for a small community collection system that discharges directly into Three Rivers, after UV disinfection. The average annual design flow is 17,000 gpd (64,400 L/d) with a peak daily design flow of 80,000 gpd (303,000 L/d) to account for I&I contributions from the collection system. Effluent BOD5 and TSS are averaging 4.4 and 4.5 mg/L, respectively. |

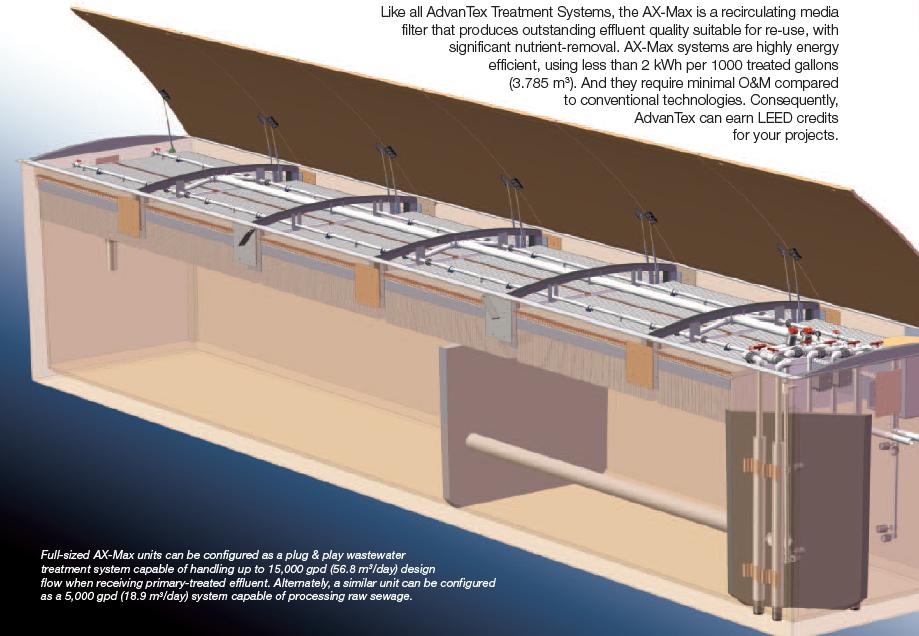

AdvanTex AX-Max™

|

APPLICATIONS:

• Municipal systems • Subdivisions, apartments • Golf course developments, resorts • Manufactured home parks • Parks, RV parks, campgrounds • Schools, churches, businesses • Rest areas, truck stops |

Reliable, Energy-Efficient Wastewater Treatment

Everywhere!

|

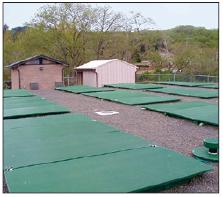

The Yakama Nations Housing Authority in Washington state added five AdvanTex® AX-Max units (background) to its ten AdvanTex AX-100 units, increasing the capacity of its wastewater system by 50%. Photo courtesy of Fextex Systems, Inc.

|

For nearly 15 years, Orenco’s AdvanTex® Treatment Systems

have been providing reliable, energy-efficient wastewater treatment inside and outside the urban core. AdvanTex textile filter technology has been winning awards and coming out on top in field trials and demo projects, all over the world. Orenco’s newest product in the AdvanTex line is the AX-Max™: a completely-integrated, fully-plumbed, and compact wastewater treatment plant that’s ideal for commercial properties and communities. It’s also ideal for projects with strict discharge limits, limited budgets, and part-time operators. |

A Sustainable Solution

|

For Every

|

|

AX-Max systems provide excellent treatment anywhere, and they have been installed all over the world. For example, AX-Max systems have been installed in-ground at Malibu’s famous beach parks, the Boy Scout’s National Jamboree site in West Virginia, and New Zealand’s resort at Glendhu Bay. Two more were recently installed in-ground in Soyo, Africa, to serve a new hospital.

Other AX-Max systems have been installed above-ground on top of Alaska’s frozen tundra and St. Lucia’s volcanic rock. Still more have been installed above-ground in mining camps from Alberta to Texas and, in the Midwest, at a U.S. Department of Defense demo site. |

Benefits

~ Significant reductions in ammonia, total

nitrogen

- Containerized, fully-plumbed

- Capable of meeting stringent effluent limits

~ Significant reductions in ammonia, total

nitrogen

- Portable, versatile, and compact

- Above-ground or in-ground installation

- Easy to set

- Simple to operate

- Low energy usage: <2 kWh per 1000

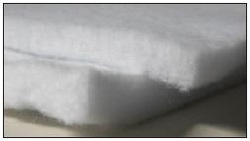

Textile Treatment Media

The treatment medium is a uniform, engineered textile. AdvanTex textile is easy to clean and

allows loading rates as high as 50 gpd/ft2 (2000 L/day/m2).

The treatment medium is a uniform, engineered textile. AdvanTex textile is easy to clean and

allows loading rates as high as 50 gpd/ft2 (2000 L/day/m2).

Effluent Distribution

High-quality, low horsepower pumps micro-dose the treatment media at regular intervals, and

proprietary spin nozzles efficiently distribute the effluent, optimizing treatment.

High-quality, low horsepower pumps micro-dose the treatment media at regular intervals, and

proprietary spin nozzles efficiently distribute the effluent, optimizing treatment.

Telemetry Controls

Orenco’s telemetry-enabled control panels use a dedicated phone line or ethernet connection, ensuring 24/7 monitoring and real-time remote control.

Orenco’s telemetry-enabled control panels use a dedicated phone line or ethernet connection, ensuring 24/7 monitoring and real-time remote control.

Point Dume State Beach and Preserve, Southern California

In spring, 2011, Los Angeles County needed to quickly upgrade restrooms at Malibu’s Point Dume State Beach in time for the long — and busy — Memorial Day weekend.

The county’s engineer specified three AX-Max’s, one for each restroom, and the units were installed in a matter of days. Each unit was custom-painted to blend into the surrounding sand or asphalt.

After disinfection, the treated effluent is dispersed right into the sand. Point Dume is part of a large-scale upgrade of L.A. County beach parks, virtually all of which include AdvanTex Treatment Systems of various sizes and configurations.

In spring, 2011, Los Angeles County needed to quickly upgrade restrooms at Malibu’s Point Dume State Beach in time for the long — and busy — Memorial Day weekend.

The county’s engineer specified three AX-Max’s, one for each restroom, and the units were installed in a matter of days. Each unit was custom-painted to blend into the surrounding sand or asphalt.

After disinfection, the treated effluent is dispersed right into the sand. Point Dume is part of a large-scale upgrade of L.A. County beach parks, virtually all of which include AdvanTex Treatment Systems of various sizes and configurations.

AdvanTex® AX-Mobile™

|

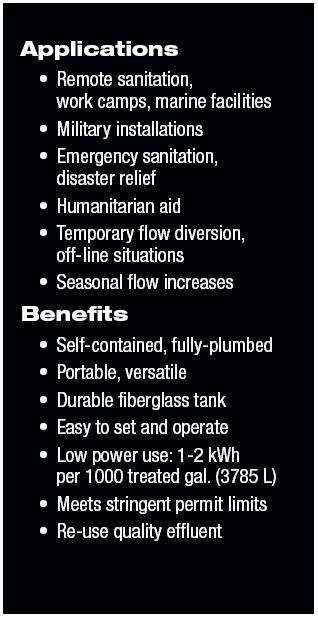

Serving 3 to 3,000 Persons:

• Remote sanitation, work camps, marine facilities • Military installations • Emergency sanitation, disaster relief • Humanitarian aid • Temporary flow diversion, off-line situations • Seasonal flow increases |

Get reliable, energy-efficient Wastewater Treatment ... Anywhere! |

|

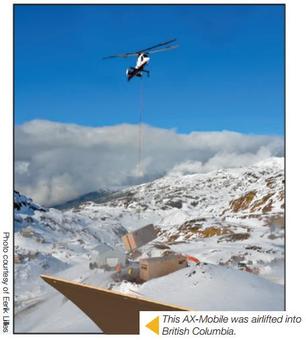

Mining camps in Alberta and Texas. A pipeline response station in the

Yukon. An oil drilling platform in Cook Inlet. A hurricane-devastated resort in St. Lucia. For more than a decade, Orenco’s AdvanTex® technology has provided reliable, energy-efficient wastewater treatment in some of the world’s most remote places. Now, the AdvanTex AX-Mobile™ is Orenco’s most portable treatment plant yet. |

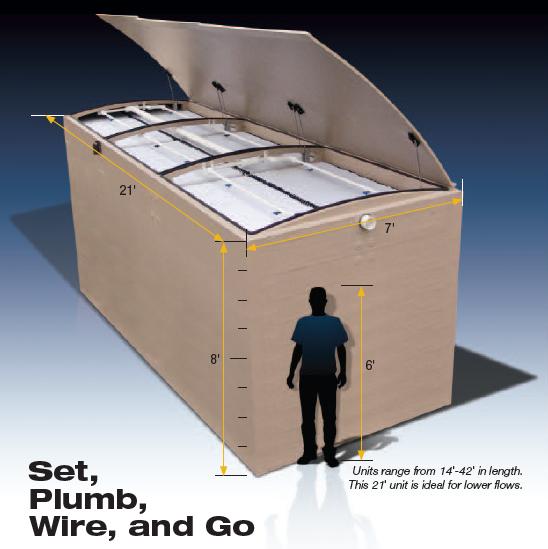

Set, Plumb, Wire, and GoThe AX-Mobile is pre-plumbed and easy to install. All the treatment media, pumps, and controls are included. Optional equipment for reducing solids or meeting more stringent permit limits (such as UV disinfection units) can be pre-installed as well. Consequently, AX-Mobile projects can meet the tightest deadlines. For example, an AX-Mobile system was up-and-running on the Caribbean island of St. Lucia four weeks after initial client contact, allowing a hurricane-devastated resort to re-open in time for Christmas holiday bookings (see below).

Tech Support by OrencoOrenco has been in business for nearly 35 years and the company has earned an industry-wide reputation for outstanding customer support. This always matters,

but it’s especially important when your wastewater system is in a remote and isolated location.

|

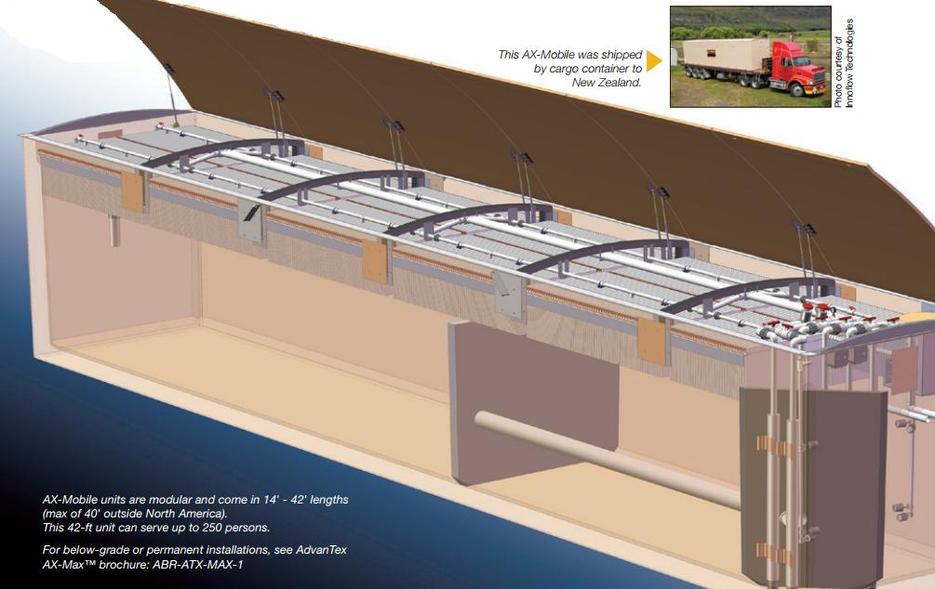

Persons Served*

• AX-Mobile-21: up to 125 persons • AX-Mobile-42: up to 250 persons • Multi-unit arrays: 3,000+ persons * Number of persons served is affected by or- ganic, inorganic, and hydraulic loading, as well as system configuration. Dimensions** • 14'-42' x 7' x 8' (4.3-12.8 m x 2.1 m x 2.4 m) **Outside North America, max length 40' The AX-Mobile uses textile sheets in a packed bed media filter. It can treat blackwater and greywater

to a level where effluent can be reused for surface or subsurface irrigation or for dust control (as regulations permit). High-quality, low horsepower pumps micro-dose the treatment media at regular intervals, and proprietary spin nozzles efficiently distribute the effluent, optimizing treatment.

The remote telemetry control panel for an AX-Mobile Treatment System is typically installed at the end of the unit and pre-wired.

|

|

Carrizo Springs Miner’s Camp,

Catarina, Texas An AX-Mobile Treatment System was installed at Carrizo Springs in Texas to serve a 233-person miner’s camp with bunkhouses and kitchen. The client wanted a completely pre-plumbed, pre-wired, mobile system that could be moved to another mining site in the future. The system includes a controls cabinet at the end of the unit and a foldup catwalk for operators. It also includes a pre-installed UV disinfection system. The system was commissioned in August 2011 and effluent sampling shows it is producing effl uent BOD of 8 mg/L and TSS of 11 mg/L, while running at 100% of daily design capacity. |

|

Alyeska Pump Station,

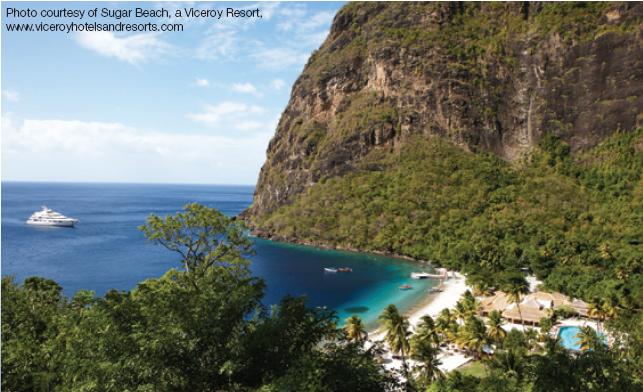

Alaska An AX-Mobile Treatment System with optional control room was purchased by the Alyeska Pipeline Company for a remote site serving up to 44 pipeline workers in central Alaska, where winter temperatures can be as low as -60° F (-50° C). The system had to be properly designed and insulated to allow the necessary biological treatment processes to function optimally, yearround. In addition, since the system was installed above ground, on permafrost, it had to meet strict NPDES permit requirements for surface discharge, since subsurface discharge was not an option. The system was commissioned in December 2009 and sampling shows that effl uent quality is averaging BOD of 6 mg/L, TSS of 5 mg/L, and fecal coliform of 5.9 MPN/100 m/L. Sugar Beach, a Viceroy Resort,

St. Lucia An AX-Mobile was installed on this award winning, 60-cottage resort on the island of St. Lucia, in the Caribbean. It replaced an old activated sludge plant that was destroyed by Hurricane Tomas on Oct. 31, 2010. Orenco was brought into the project on Nov. 18 and had the system shipped, installed, and commissioned by the resort’s December 20 re-opening date. At only 7' (2.1 m) wide and 12,000 pounds (5443 kg), the units were trucked to the site, down steep narrow roads, on the back of a standard fl atbed and lifted with a crane. Less than two days after reaching the site, the system was up and running, in spite of power fluctuations and other problems. This system includes a UV disinfection unit, and effluent sampling shows it is producing 7 mg/L BOD. An addition to the treatment systems is currently in process. |

IDEAL FOR COMMUNITIES OF ALL SIZES:

New subdivisions • Neighborhood clusters • Commercial properties • Sewer expansions

• Septic tank abatement • Ecologically sensitive areas

Any site conditions: flat, hilly, shallow bedrock, high groundwater

New subdivisions • Neighborhood clusters • Commercial properties • Sewer expansions

• Septic tank abatement • Ecologically sensitive areas

Any site conditions: flat, hilly, shallow bedrock, high groundwater

Choose the Superior Wastewater Solution:

Orenco Effluent Sewers

Communities and developers throughout the world are struggling with wastewater

collection and treatment issues. For many areas, conventional gravity sewer

systems are too costly. Moreover, conventional sewers are not watertight, so their

overflows contaminate our rivers, bays, and oceans.

collection and treatment issues. For many areas, conventional gravity sewer

systems are too costly. Moreover, conventional sewers are not watertight, so their

overflows contaminate our rivers, bays, and oceans.

|

" Given the diversity of the new technology that is now being developed, it is reasonable to speculate that, in the future, the continued use of gravity flow systems will be a thing of the past. "

Dr. George Tchobanoglous, UC Davis, Author of Wastewater Engineering: Treatment, Disposal, Reuse and Small and Decentralized Wastewater Management Systems " Managed decentralized wastewater systems . . . merit serious consideration in any evaluation of wastewater management options for small and mid-sized communities and new development. "

EPA, Response to Congress on Use of Decentralized Wastewater Systems, April 1997 |

Watertight effluent sewer systems are becoming recognized as one of the best solutions for collecting waste and transporting it to a treatment facility.

Orenco has helped hundreds of small communities throughout the world to design, build, and maintain low-cost, watertight, reliable effluent sewers. Depending on terrain, effluent sewers are often half the cost of conventional sewers, or less. And Orenco Effluent Sewers come with VeriComm® Control Panels and their Web-based Monitoring System. So operators can monitor and maintain the system remotely, from the office or home. For residents, that means continuous supervision and 24/7 peace of mind. |

There are other alternatives to conventional sewers - grinder systems, for example. However, because the effluent from an Orenco Effluent Sewer is relatively free of grease, oil, and solids, the pumps and collection lines require less maintenance. And the high-quality filtered effluent from an Orenco Effluent Sewer requires less costly treatment.

For all these reasons, communities that purchase our effluent sewers enjoy system-wide, long-term savings. |

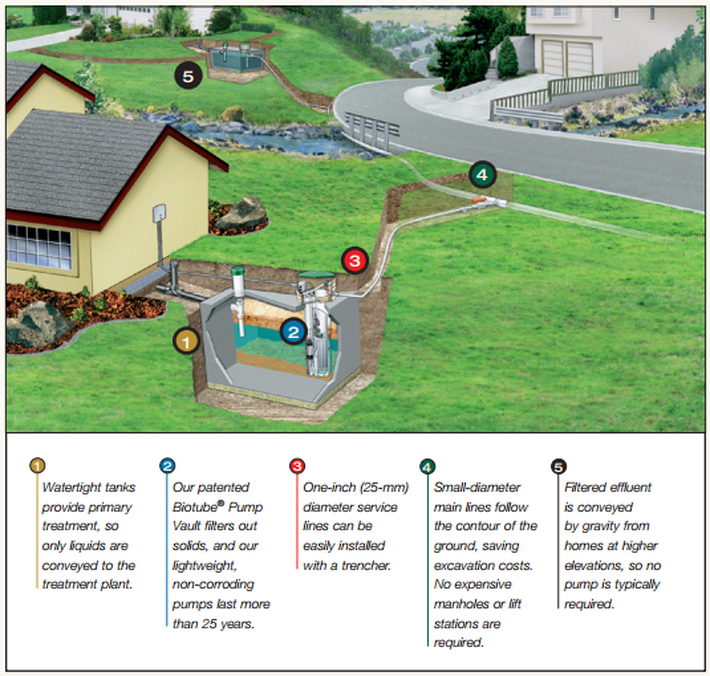

How an Orenco Effluent Sewer Works

|

With an Orenco Effluent Sewer, raw sewage flows from the house or busi-ness to a watertight underground tank, where it is pretreated. Only the filtered liquid is discharged (by either pump or gravity) through the service lines, to shallow, small-diameter collection lines that follow the contour of the land. Solids remain in the underground tank, for passive, natural treat-

ment. Tanks typically need pumping only once every 10-12 years. |

|

This photo shows phase 1 and 2 of Orenco's modular AdvanTex AX100 Wastewater Treatment System, located in Bethal Heights, Arkansas. Bethal Heights now has 45 AX100 filter modules that are designed to handle 850m3/day of wastewater. Multiple Orenco telemetry panels control the small, low-energy pumps that move wastewater through the filters and out into the drip irrigation fields.

|

From Sewer to Treatment

The high-quality, filtered effluent from an effluent sewer is ideal for use with a low-cost, low-maintenance treatment system, such as a recirculating sand filter or Orenco's AdvanTex® textile filter. From there, it can be reused for irrigation or to recharge groundwater. With no infiltration or solids to contend with, the treatment plant can be sized up to 90% smaller than with other collection technologies. Orenco's Effluent Sewers are designed as a totally integrated package, and system components are compatible and pre-assembled. Each item is fully warrantied, and components are corrosion-resistant, durable and lightweight. |

A Fraction of the Cost of Conventional Sewers

Orenco Effluent Sewers dramatically reduce short-term and long-term wastewater

treatment costs for communities and developers. In fact, effluent sewers are often one-

half the cost of conventional gravity sewers or less. Here are the many ways you save:

treatment costs for communities and developers. In fact, effluent sewers are often one-

half the cost of conventional gravity sewers or less. Here are the many ways you save:

|

Save On

Equipment And Labor

|

|

Save on Operation And Maintenance

|

Save On Treatment Costs

|

|

“In general, alternative collection systems should

be considered for smaller rural communities with low population density and site specific environmental conditions . . . Shallow bedrock, high groundwater conditions, extremely flat or very hilly terrain and limited room for construction make alternative collection systems more cost-effective than conventional systems.” Illinois Community Action Association Alternative Wastewater Systems in Illinois Orenco Effluent Sewer Systems

are ideal for new subdivisions, whether on flat ground or on the most difficult terrain. |

Hundreds of communities throughout North America are successfully collecting

and treating their wastewater with Orenco Effluent Sewer Systems.

|

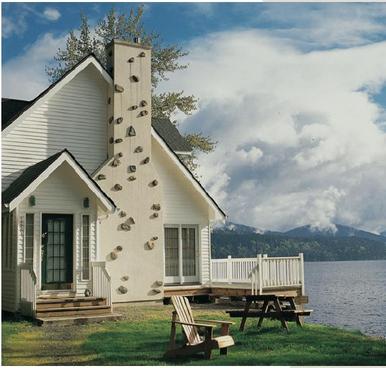

Diamond Lake,

Washington In 1986–87, an Orenco Effluent Sewer system serving 500 homes was installed in this Washington lakeside community. Half the properties are seasonally occupied, with sudden start-ups and prolonged shut-downs. And the winters are very cold. Even so, operator Larry Garwood said, “The systems are simple, dependable, and easy to maintain.” New Minden, Illinois The small farming community of New Minden, Illinois (pop. 228) is attracting nationwide attention for its Orenco Effluent Sewer and recirculating gravel filter. Built for little more than $1 million — half the cost of the gravity sewer bid — the system produces such clean effluent (BOD and TSS below 3.0 mg/L) that it discharges to a stream. Cost per dwelling? Less than $8,000 for collection and treatment. |

Elkton,

Oregon In 1989, an Orenco Effluent Sewer system was installed to serve more than 100 homes and businesses in Elkton, Oregon, at an average cost of less than $7,000 per home for both collection and treatment. Ten years after installation, maintenance on the entire collection system averaged less than one hour per month, and not a single residential septic tank needed pumping. Steamboat, Oregon In 1999, an Orenco Effluent Sewer, followed by an innovative textile filter treatment system, was installed in Steamboat, Oregon, to replace a leaking gravity system along a wild and scenic river. Annual operating costs have been reduced by a factor of 12! Mobile, Alabama In the 1990's, South Alabama Utilities realized they needed to provide wastewater services to new subdivisions or risk losing customer share.Since then, SAU has installed Orenco effluent sewer systems serving 47 subdivisions. When all the developments |

|

Effluent Sewer Systems have been in use for several decades. During that time,

the technology has improved so dramatically that effluent sewers are highly

recommended by the U.S. Environmental Protection Agency, as well as by

engineers, academics, and public agencies.

|

Do pumps have to be repaired or replaced frequently?

No. With normal maintenance and cleaning, our pumps last more than 25 years. Plus the electricity to run them averages less than $1 per month. Will the system smell? No. Not if properly designed and installed. Any wastewater collection system will smell if not properly designed and installed. I’ve heard stories about these systems failing. Are they true? Orenco Effluent Sewers work well. Solid engineering, proper equipment, and attention to detail ensure that. With any type of sewer system, poor engineering, substandard equipment, or sloppy installation can cause problems. Orenco Effluent Sewers have a well-documented track record of success. Is the underground tank hard to take care of? No. We require watertight tanks, and most need pumping only once every 10–12 years. Otherwise, they’re underground, out of sight and out of mind. |

What happens to the solids that accumulate in the tank?

Accumulation of solids occurs slowly because of the digestion process that takes place in a watertight tank. In fact, the tank digests more than 80% of the biosolids. Remaining solids are easily managed through planned pumping schedules. What if something goes wrong with my tank? Each property has a control panel with an alarm function. Your system’s operator will be automatically notified of any alarms. And the 24-hour reserve space in your tank gives the operator time to have a problem checked. If I have more questions, whom can I talk to? Send us an email inquiry through our contact page . . . |

|

Carefully Engineered by Orenco

Orenco Systems has been researching, designing, manufacturing, and selling leading-edge products for small-scale wastewater treatment systems since 1981. The company has grown to become an industry leader, with about 250 employees and with more than 300 points of distribution in North America, Australasia, Europe, Africa, and Southwest Asia. Our products and technologies have been installed in more than 60 countries all over the world. Orenco maintains an environmental lab and employs dozens of scientists and engineers. Orenco’s systems are based on sound scientific principles of chemistry, biology, mechanical structure and hydraulics. As a result, our research appears in numerous publications and our engineers are regularly asked to give workshops and offer training. |